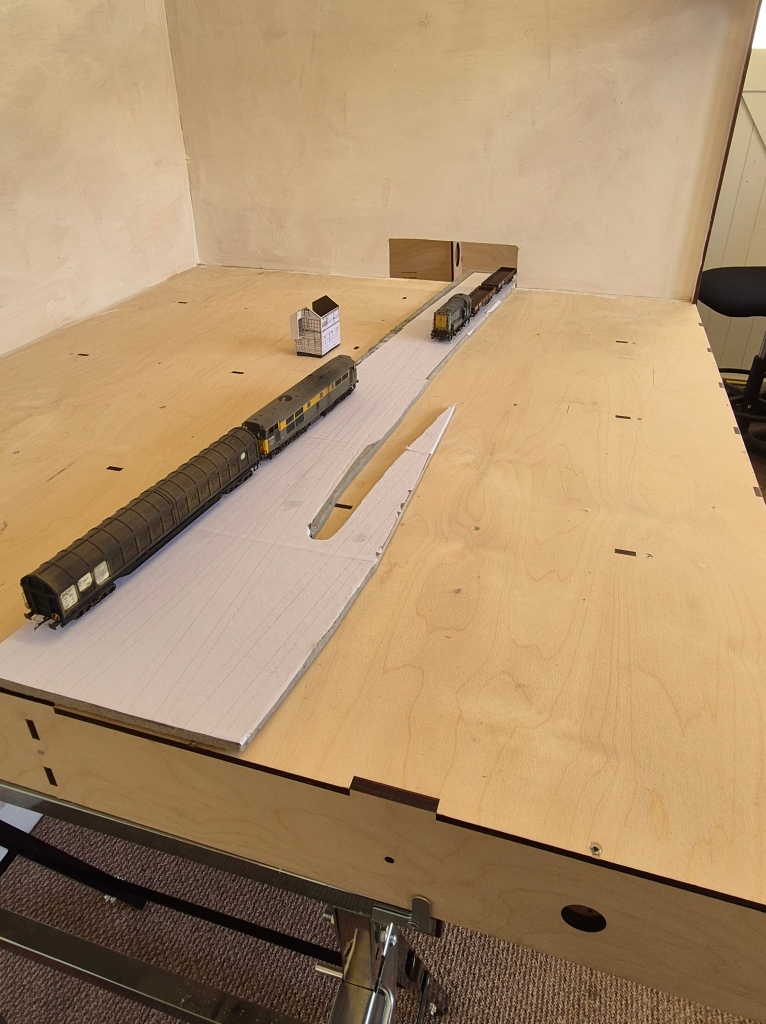

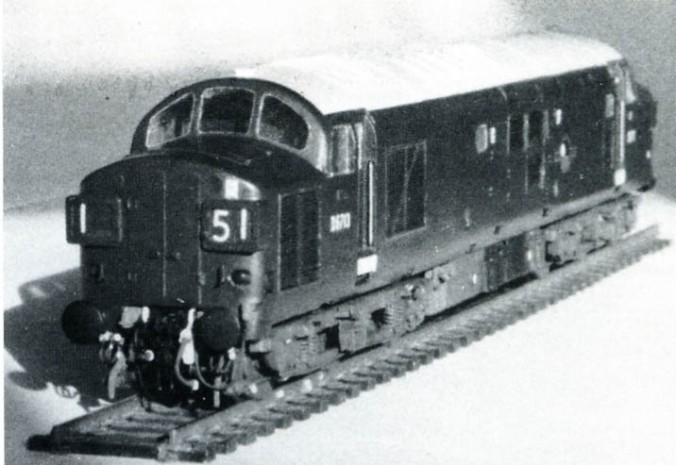

The class 37 is one of my very favourite locomotives – there’s something rather special about them, their looks, longevity, coats of many colours and, of course, the noise!

The new Accurascale Class 37.

The British Railways English Electric Type 3, perhaps better known as class 37, was introduced in 1960. The type has become one of the most versatile and longest-serving locomotives on Britain’s railway network. With a distinctive body design and a 1,750 horsepower engine, the class 37 was renowned for its reliability and performance. Despite their age class 37 locomotives are still in operation today, notably with Direct Rail Services and Colas Rail. This long lifespan certainly makes it a great commercial choice for the RTR manufacturers. Tri-ang (later Hornby) first introduced their 4mm model in 1968.

Nick Hardcastle’s model based on the Tri-ang model is still my favourite of all models of the type I’ve seen. It’s the one to beat.

Since then we’ve had many Lima version and about twenty years ago Bachmann gave us their first attempt at a class 37/4, with many issues with its shape but it ran very well. It’s since been through various incarnations and developed into a pretty decent model. Later Vi Trains gave us their version too, which had some delightful moulded details.

Any model developments catch my interest, so going back to late 2019 and our first glimpse of Accurascale’s class 37. You see I was quite impressed with the initial samples. How does that initial impression compare with my impression of the final version?

I did suggest to the Accurascale MD, Stephen McCarron, to let us have a preproduction to look at here on a thread on LinkedIn but he didn’t seem to be up for the challenge. A shame but I’d ordered one back in early 2020 and after a three and a half year wait 37051 arrived.

Overall, upon first impression, it looks like a class 37, so that’s a good start. It runs well, in the limited amount of running it’s had. I think we can take decent running as a given these days.

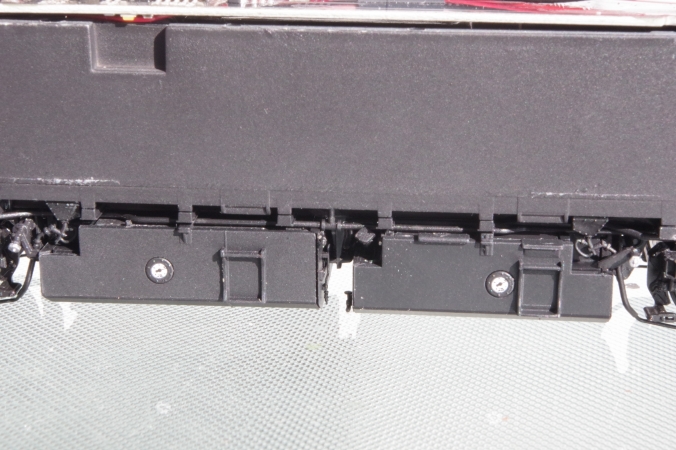

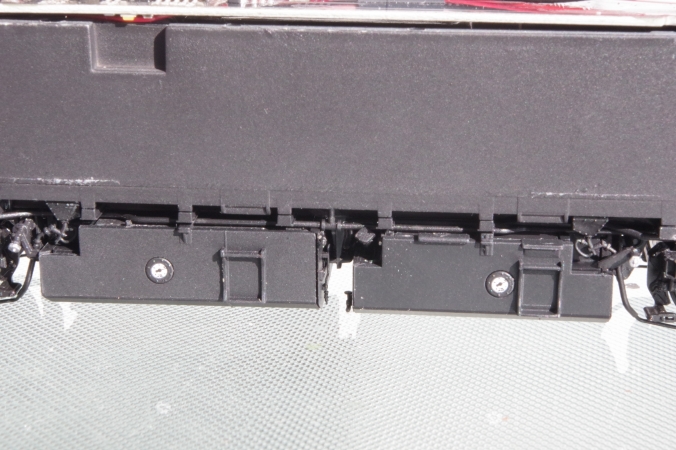

The bogie detail is particularly nice.

The first thing which I noticed was the underframe, it looks very good – there’s a lovely amount of depth to it. The bogies are nicely done too. Fortunately the class 37 doesn’t suffer from the comically small wheels that its Deltic sibling does. The axle boxes line up too whereas the Deltic’s axle boxes don’t. Its wheels are decent looking too – only a few years ago RTR diesel wheels looked very poor, and not just Lima!

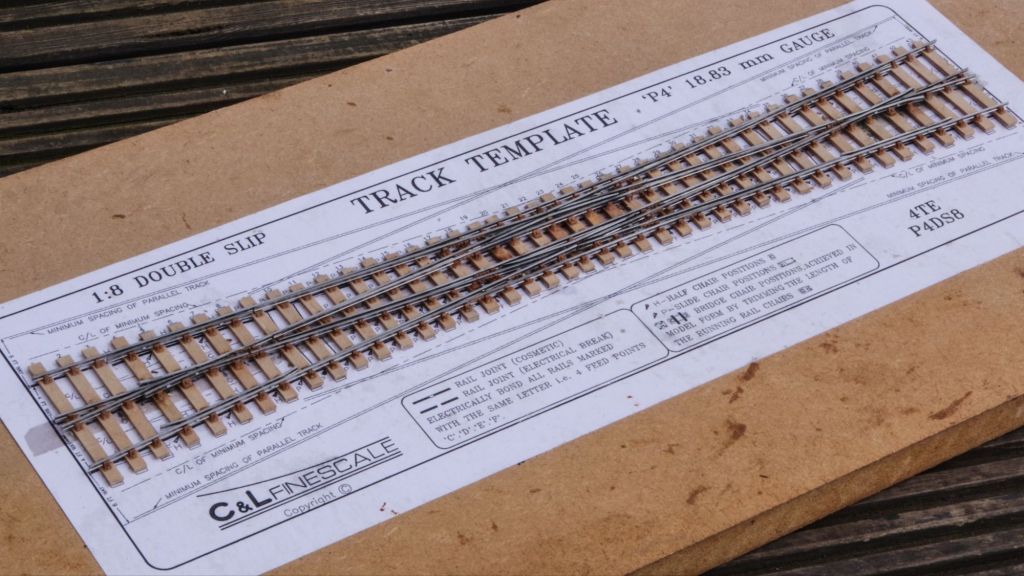

Accurascale produce drop in wheel conversions for EM and P4 but we’ll have a look at that in another post, another time.

Accurascale P4 wheelsets.

Carefully handling around the details on the underframe is required when removing the body as some feel very delicate – one the cab door steps popped off during handling (just out of the box) so just be careful and inspect details so you can secure them.

The underframe is a real delight!

The brackets around the underframe tanks are rather pleasing – I’ve added these to various models over the years and it fills what would otherwise be unwelcome daylight between the bogies and tanks. Weathering will really bring the area to life. I think there’s still room for extra detailing here too.

I was quite taken by the cab interiors – Hornby set the bar with interiors of their new generation of diesels in the early 2000s and these here are to a decent standard. Anyone who has scratch built their own diesel cab interiors will know how much work this would otherwise be! Accurascale in connection with Modelu have produced crews for them, precoloured 3D printed items, but I’ll use one from Modelu’s regular range, just to be different I guess.

Cab interior.

Cab interior.

Cab interior and control desk.

The buffer beams are nicely done, the steps on the corners are a nice addition – even I’ve not added them often on 37s in the interests of durability. The multiple working socket looks a bit undernourished and is the only one of the buffer beam pipes/cables to be pre-fitted. The air pipes look really nice but I’m far from convinced about the vacuum pipes. Buffers are nicely shaped and moulded but their shanks stick out like a sore thumb as these ones don’t polish themselves like other types do. I’m also not keen on plastic buffer heads – if you use couplings which require the buffers to be functional, 3 links, Sprat and Winkle, etc, then they might not look great after a while. I much prefer blackened metal heads. Something to investigate though.

The nose, cab and windscreen.

The overall shape, size and proportions of the body are pretty good. There are some issues.

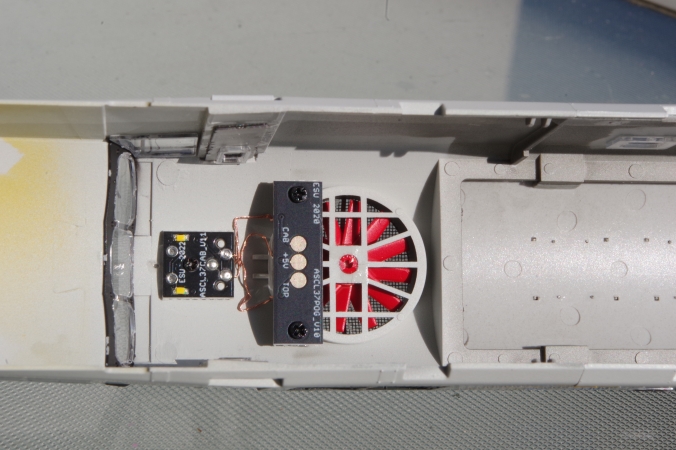

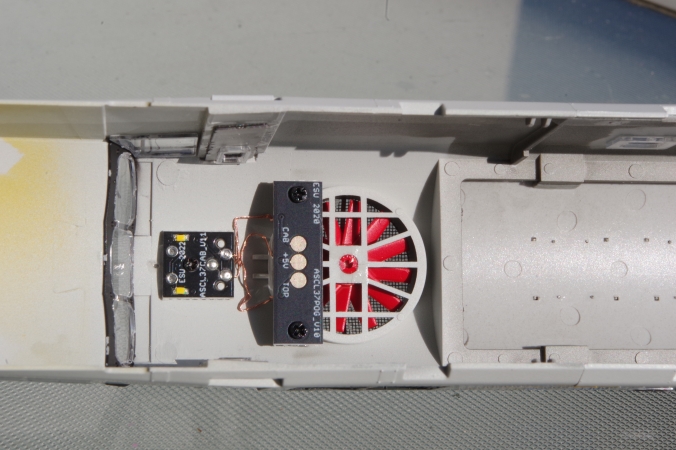

The fan grille.

The roof of a model tends to be an area we focus on more so than we ever would the real thing. As such a model’s roof has to be good – that’s why we fitted A1 Models’ fan grilles back in the nineties! The Accurascale fan grille is a world away from the old A1 Models roof grilles. I was impressed with how strong it seems whilst looking quite good. It’s not quite as good as a Shawplan Extreme Etchings grille, so I’d look to replace the RTR item. The strange thing is that the fan itself is trapped by the fan grille which may make respraying awkward.

The trapped fan and cab lighting.

A large portion of the roof is removable to allow access to the decoder for fitting, etc. It does result in a body with much less structural integrity if the body isn’t on the chassis – it will avoid the awkward removal of the body I suppose but in all likelihood how often will access be required? I’m tempted to permanently fix it in place. Before then the roof needs some work.

The rather too prominent roof hatch hinges. The join between the removable roof panel and the rest of the body seems very noticeable here.

The roof hatches have hinges which stand proud of the roof – there is daylight between these hinges and the roof in reality but on the model they stand too proud looking more like handrails. These will need repositioning to get the correct appearance.

The roof hatches on the real thing, not how the hinges sit here.

Does the exhaust panel sit too proud of the roof?

Body side grilles – is the exhaust too prominent?

The body sides are nicely done, the standard of moulding is very good – the panel lines along the lower portion of the body and tumbleholme are nicely done with some nice subtle bolt head detail. The noses are reasonably good, though the fit of the door is poor I felt, not a design flaw but appears to be a manufacturing issue. I’m going to look at improving the fit, at least seeing if it can be improved. Being able to remove the door will make modelling those locos with sealed doors easier. Another benefit will be it’ll be easier to touch up the missing yellow on the headlight brackets. As it comes this bracket appears too prominent but touch up work should make quite a difference for not much effort.

The nose door removed.

Now it’s time for what has proved to be rather contentious issue – the windscreens.

Class 37 windscreens.

There’s been discussion online about the accuracy of the windscreens and it’s a hard one to really pin down. On the real thing the windscreens are within a separate panel which sits within the surround. Previously manufacturers haven’t really bothered with this – the latest class 37 from Bachmann has captured this really well though. Accurascale have approached this in a completely different way from the rest and the windscreen panel as a separate piece fitted from within the body. The fit of these is different at both ends of the example in front of me, one end looking better than the other.

Accurascale Vs Shawplan windscreens.

The moulded glazing doesn’t help things, it suffers from the parallax which virtually all moulded glazing does. A set of Laser Glaze from Shawplan, one it’s produced night help here. But I then wonder if adding the Shawplan backing plate and windscreen panels would help. Consistency across my little fleet of locomotives is key for me – I want people to see a model of a class 37, not a Bachmann one or an Accurascale one. Models of locomotives not model locomotives. The RTR product is a means to an end not an end in itself. Maybe it’s not an approach for everyone but I find it very satisfying.

A Shawplan windscreen panel placed over the Accurascale one – instant improvement? I reckon so.

The result is looking beyond the RTR model as it comes, looking how to make the best of everything. When a company MD describes their product as “definitive” does that mean my approach is irrelevant?

No.

Of course not because unless you’re looking at a locomotive built by the likes of Guy Williams, Tony Reynolds, James Beeson, Bernard Miller or Vic Green it’s not going to be “definitive”. We’re looking at a hobby which is always developing. We should be encouraging those who wish to push their modelling forward and drive standards up – even if it doesn’t satisfy the corporate line. And it’s a very satisfying way to work for me.

The finish of the paint is what you’d expect from RTR these days – there are etched BR arrows and depot plaques to place over the printed versions. I’d rather the depot plaques hadn’t been printed as the loco spent most of its time in this livery without them. If you fit the supplied snow ploughs it had lost the depot plaques by the time the real loco acquired them.

So how does the Accurascale class 37 stack up?

Well, it’s a good attempt – it should be a good basis for a project. I need to decide how to deal with the areas I’ve highlighted, let’s see how worthwhile the changes are…

Link

Accurascale Class 37